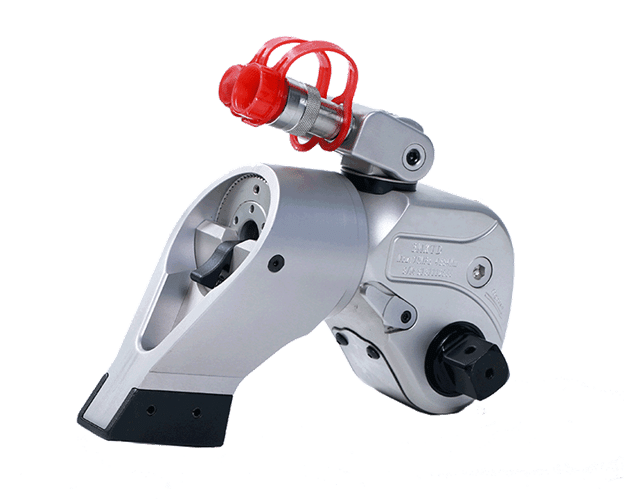

Its drive shaft drives the socket to preload the nut and is commonly used to tighten and remove bolts longer than 1 inch. Additionally, it is used with various high-strength sockets to act on multi-specification bolts within a tolerable torque range. The square drive hydraulic torque wrench is more universal than the low profile hydraulic torque wrench.

The one-piece shell can greatly improve the strength and durability of the shell. It has a longer life, is stronger and lighter and can accommodate a range of work heads with just one power head. There are no operating space limitations as 360° x 180° rotatable pipe fittings are used. You can freely position the 360° fine-tuning reaction arm on a stable pivot with the easy-press trigger lock. Each pad rotates 27 degrees and moves quickly.

TorcStark is a professional square drive torque wrench manufacturer. We have a full line of square wrenches. All products are made of aluminum titanium alloy and high strength alloy steel. One-piece hull can fully improve the strength and toughness of the hull. It has longer service life, higher hardness and lighter weight, and one power head can match a variety of working heads.

360° × 180° rotatable tube fittings are used, so the working space is not restricted. Trigger lock, easy to press, you can freely adjust the 360° fine-tuning reaction arm on a strong pivot. There is no counter pawl to prevent tool jamming. Each stroke rotates 27° and the speed is fast. With a precision ratchet, accuracy reaches ±3%. The small nose radius facilitates use in the tightest of spaces. Anti-corrosion surface treatment, suitable for use in harsh environments.

TorcSkark square drive hydraulic torque wrenches are widely used in electric power (nuclear, wind, hydro, thermal), shipbuilding, metallurgy, transportation, cement, construction, aerospace and others areas used. We have won more and more customers with amazing product quality and Get more for reasonable prices.

Why choose a square torque wrench?

- Torque wrench with square drive with continuous ratchet

- Maximum Torque 140,000 Nm (103,700 ft-lb)

- Maximum working pressure 70 MPa (10,000 psi)

- 3/4″-4″ square drive

- High repeatability with an accuracy of +/-3%

- Double acting, heavy duty

- 360 degree reaction arm

- 360X180 degree rotatable hose connector

- Compact, high-strength construction for everyone

- Hands-free disposable ratchet with easy release mechanism.

- The tool is made from high-strength aerospace-grade aluminum and titanium alloy.

- The square drive has a one-way ratcheting mechanism.

- The square drive features a decent on the tool for easy switching from tightening to loosening.

- With carrying handle (for some larger models)

- The square is used to lock the sockets with a dowel and an O-ring (optional).

- The reaction mount is parallel to the axis of the bolt and a reaction wedge is provided in the square drive assembly.

- The reaction arm can be adjusted to different angles/positions on the full 360 degree rotatable circumference.

Square Drive Torque Wrench Applications

Wind Energy

Hydraulic wrenches are generally utilized for lifting and support in the wind industry. Because of the extraordinary design of the wind turbine, the tower, nacelle, center point and edges are completely associated by spine bolts, and the number is enormous. The recurrence of purpose of the water driven wrench is high and the hardware is work serious. The advancement of the lifting work and the solidness and security of the gear are moved along. Specifically, wind hydraulic torque are regularly utilized in anchor bolts, edges on heading, orientation on centers, yaw drives, yaw course on establishment plates, yaw direction on towers, primary orientation on wharfs, gear bases, tower ribs, retractable parcels, center connectors, principal bearing retainers, variable bearing on center, variable drive, Adjustment direction at sharp edge, circle and other establishment and support focuses. Get more

Construction

With the rapid development of China’s construction machinery industry, traditional construction activities have been gradually replaced by advanced technologies. For example, in the past, jackhammers, large manual wrenches, or pneumatic wrenches were commonly used for large bolts on construction machinery.

However, because these conventional wrenches are not as large as high-torque, high-precision hydraulic torque wrenches, and many construction equipment manufacturers use hydraulic torque wrenches. . Hydraulic wrenches performance a significant role in the manufacture and installation of hydraulic breakers, shield machines, crushers, excavators and other equipment, and after-sales maintenance.

Smelt

Steel mills and foundries have stringent performance requirements for tools operating in extreme conditions that require tools to withstand intense heat, dirt and continuous use. Because of their reliability, durability and powerful features, hydraulic wrenches can easily handle the toughest jobs and adapt to the toughest environments.